Meet our new strain sensor HRSS

High Resolution Strain Sensor

Sensing beyond the limits

Simplify real-time measurement of your products with HRSS now and create new business opportunities

Innovative MEMS Microsensors for High-Resolution, Non-Invasive Diagnostics and Prognostics

Our microsensors offer unparalleled precision and bandwidth, enabling real-time, non-invasive measurement of strain, weight, pressure, force, and more.

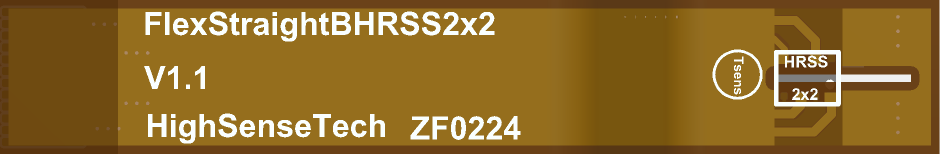

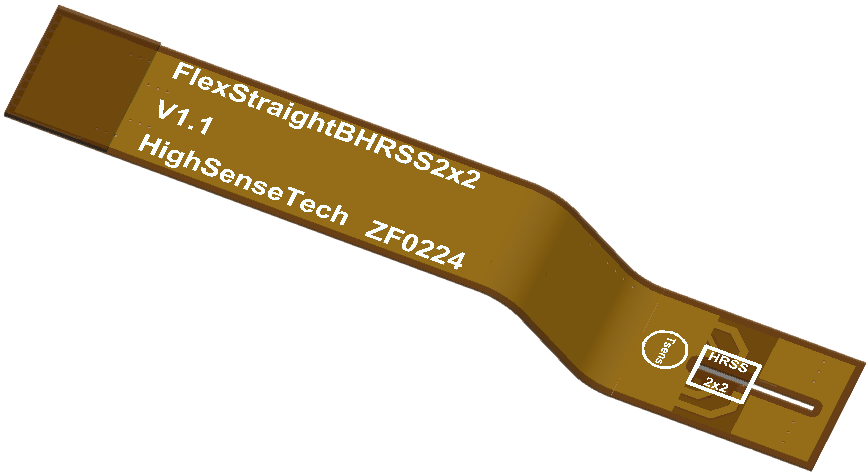

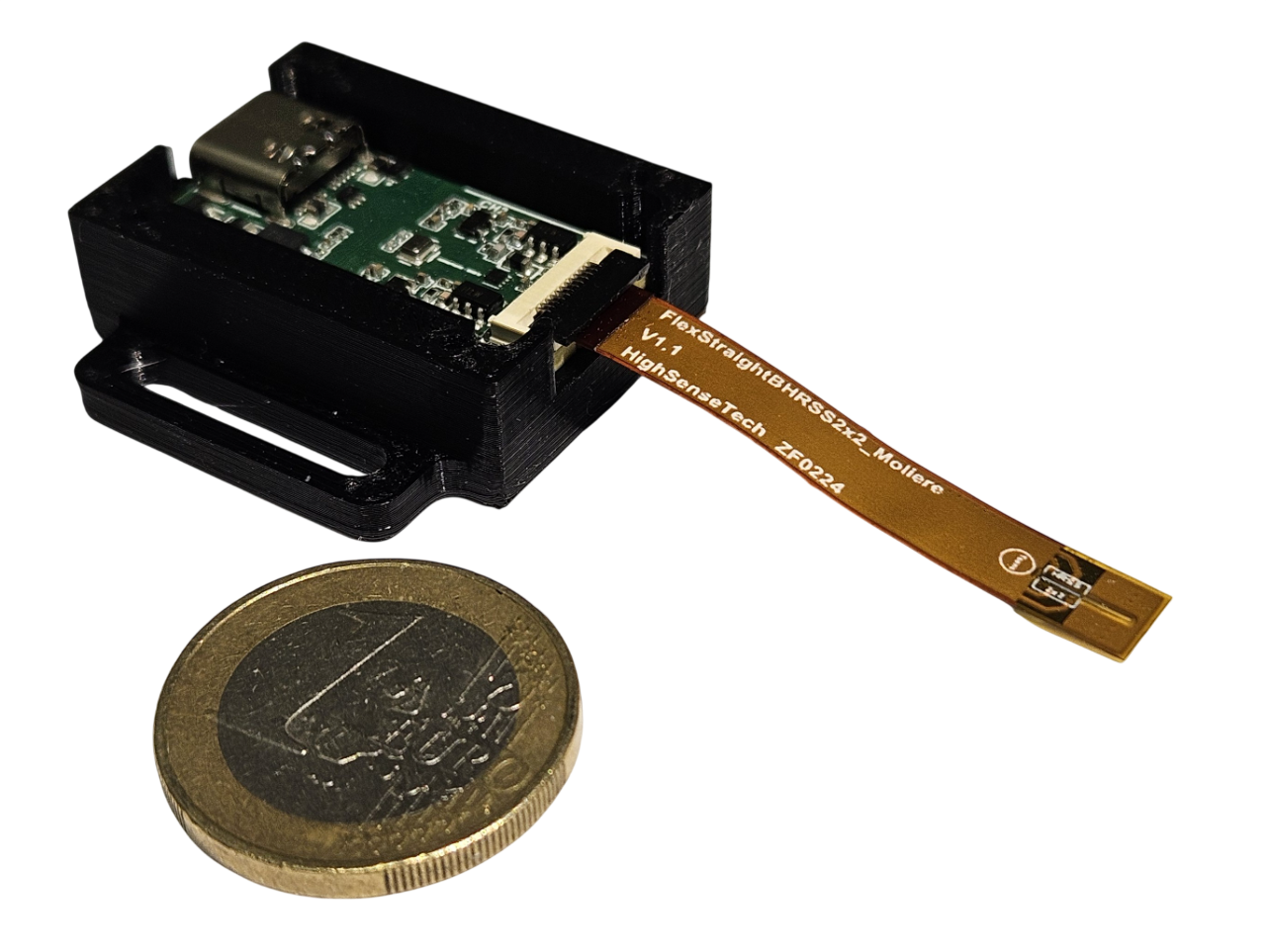

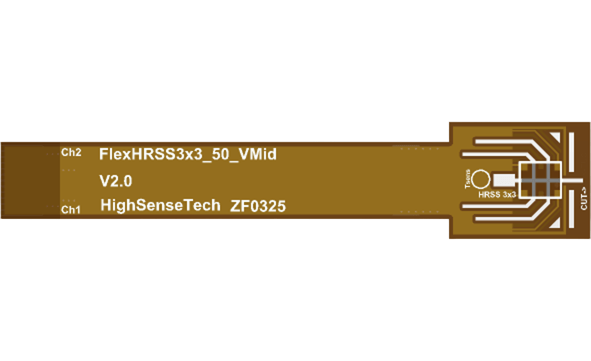

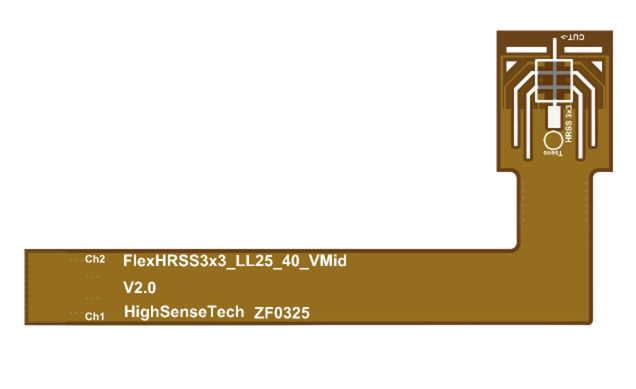

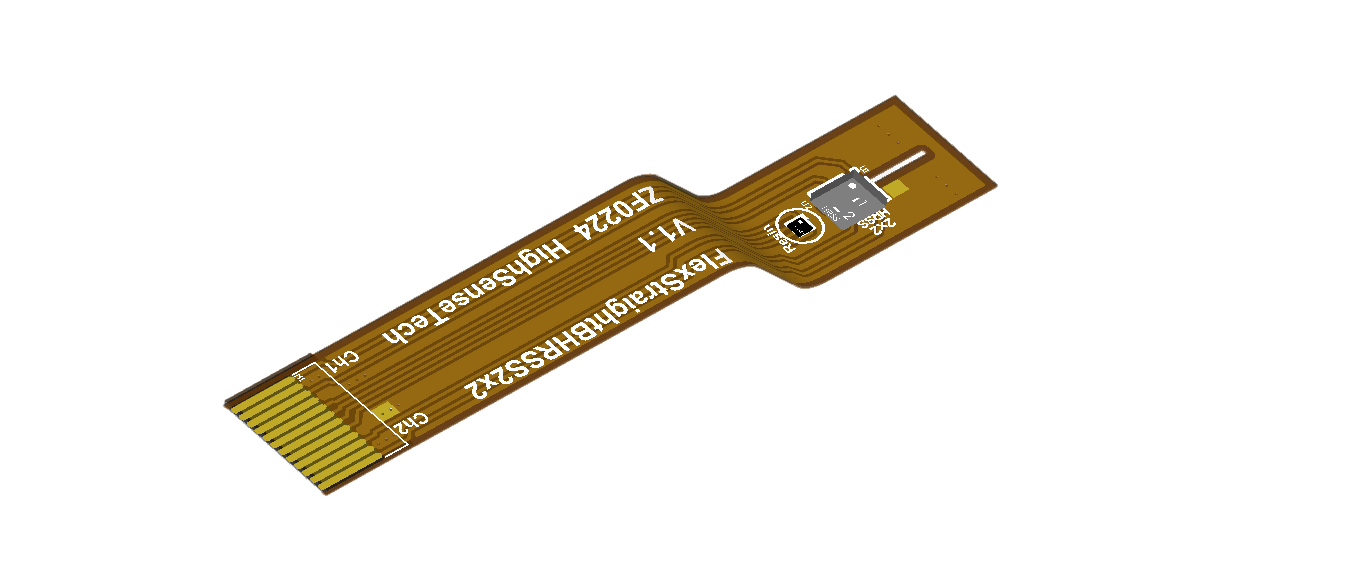

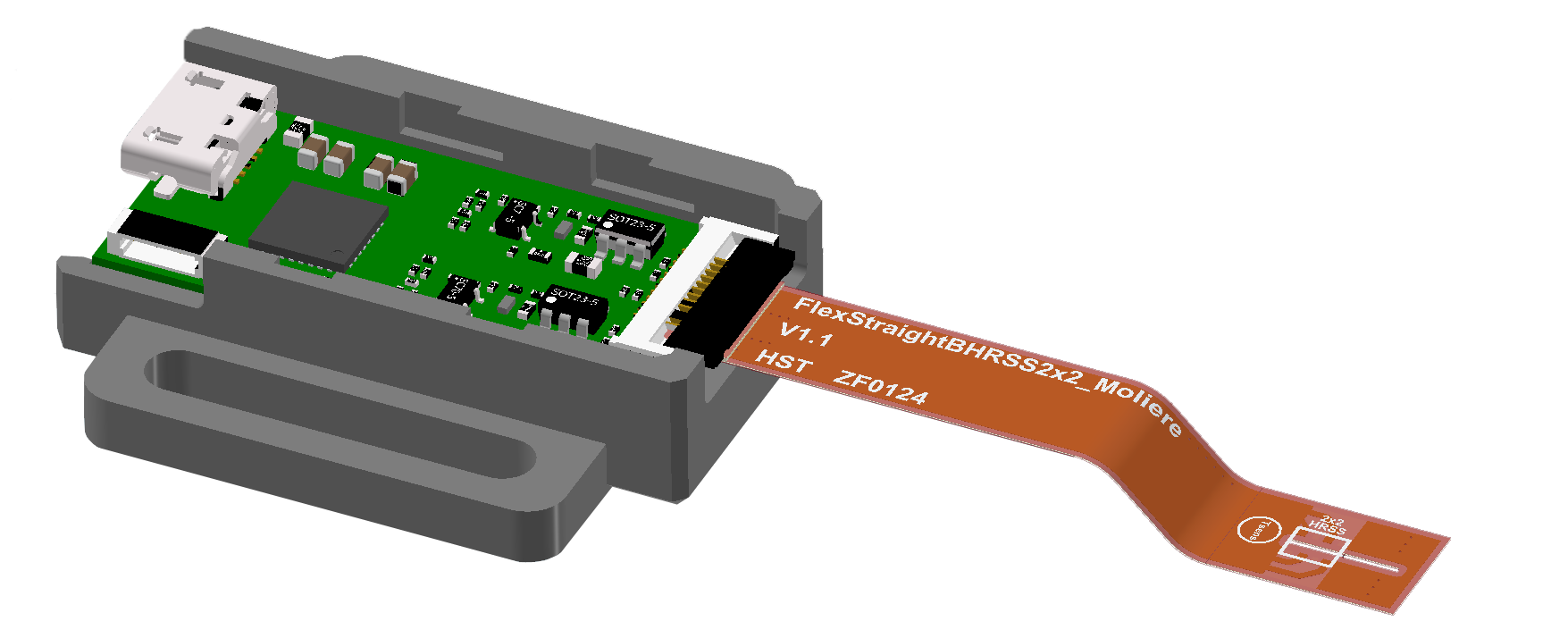

HRSS design details captured in high-resolution renders

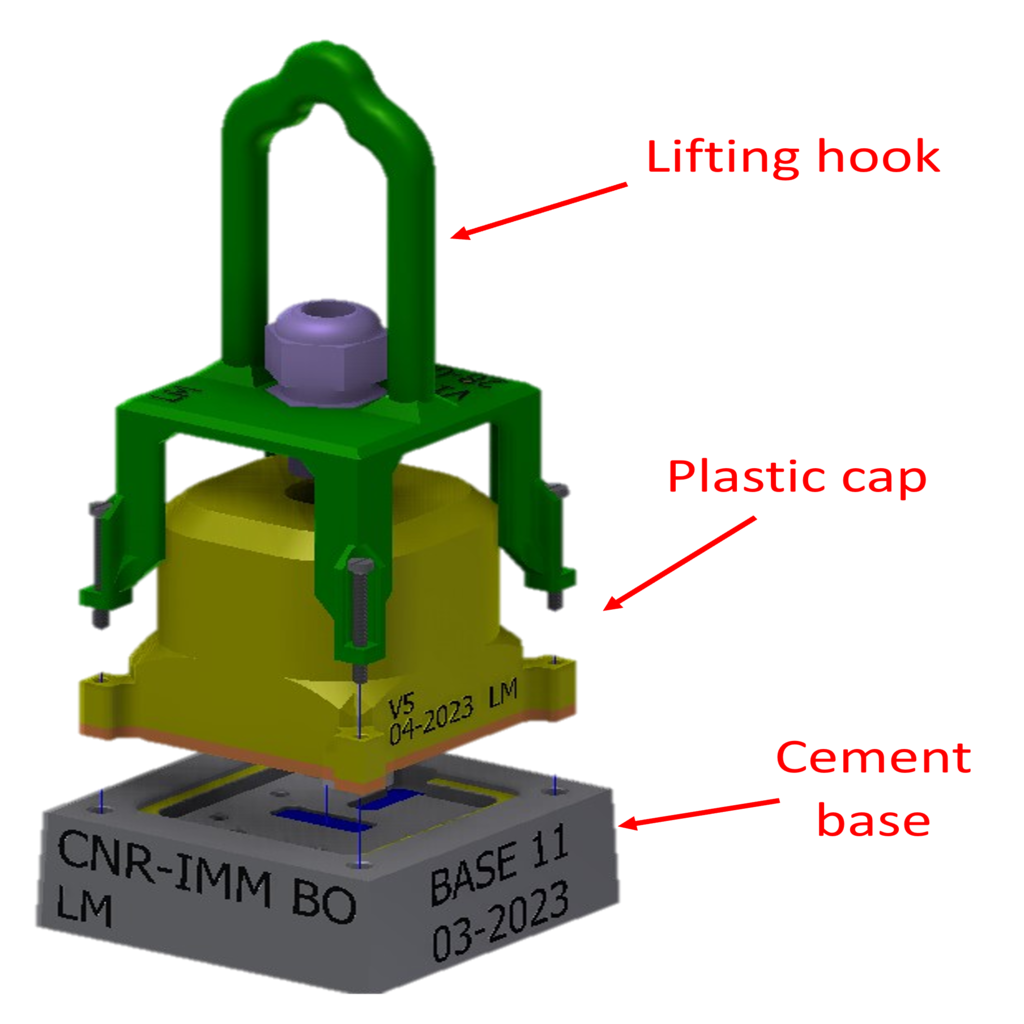

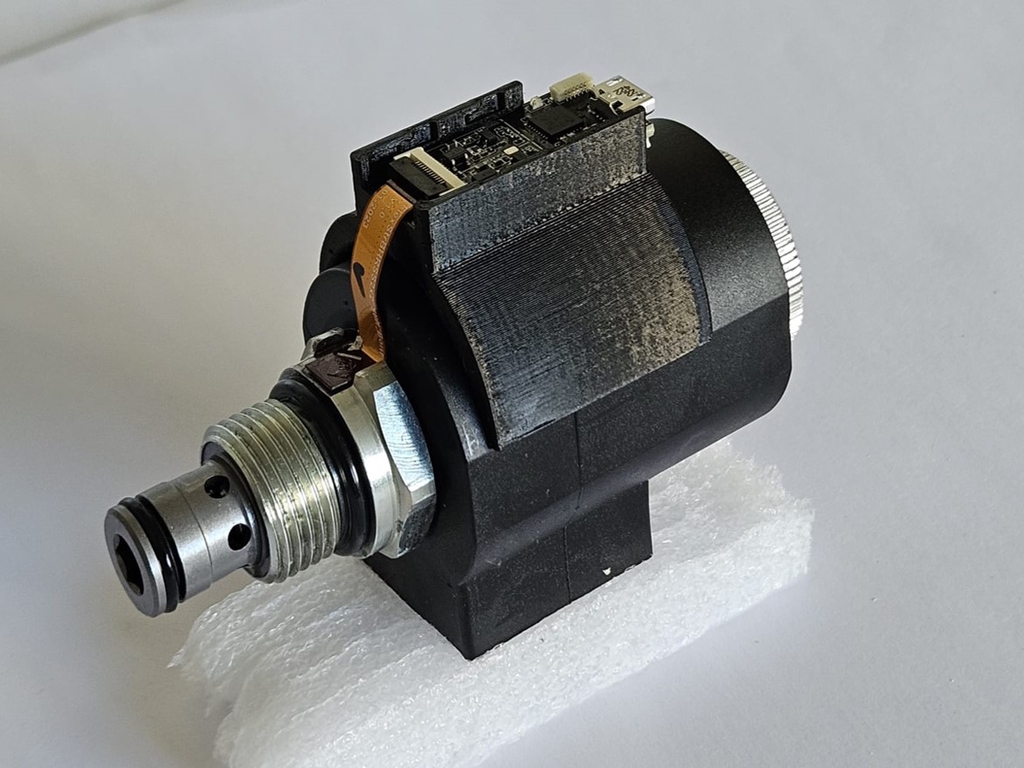

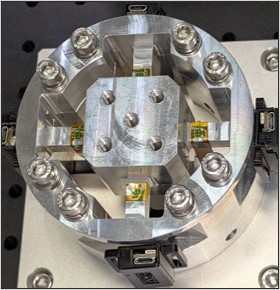

Sensorization of your device

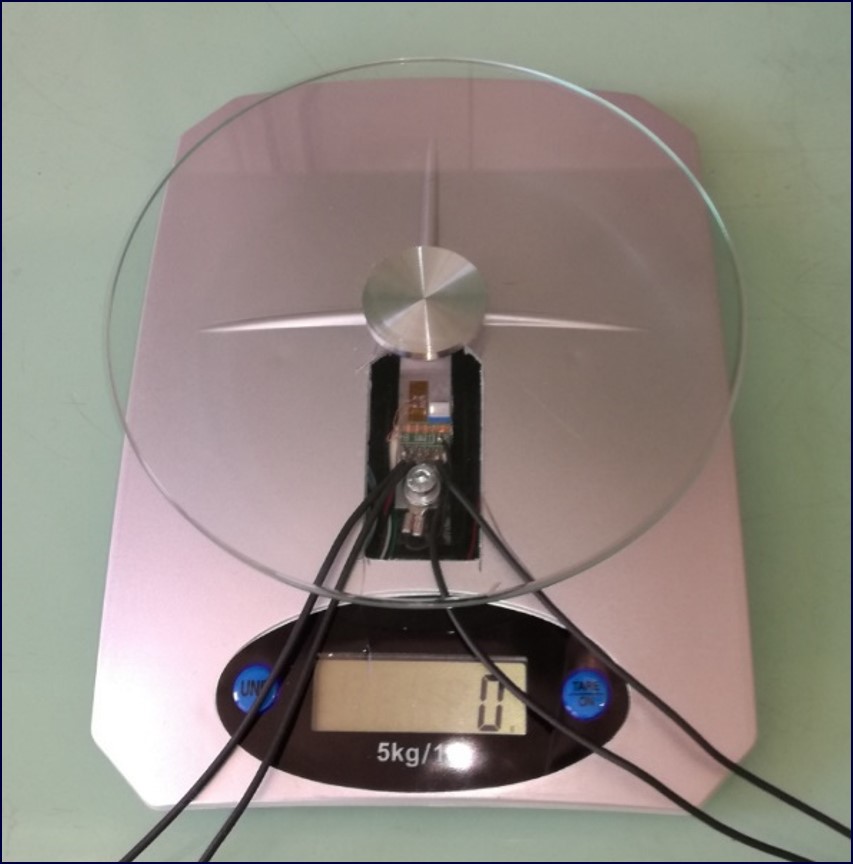

Application of our HRSS sensor and verification of the physical quantity detection

AI education

Artificia Intelligence to get the data of interest with the measurement of the related deformation

About

Discover HighSenseTech

Leading the Future of Non-Invasive MEMS Sensor Technology

HighSenseTech develops innovative and non-invasive MEMS sensors, designed for advanced measurement of physical quantities across various industries.

-

MEMS Sensor Design and Fabrication

We utilize Multiphysics FEM modeling and simulation to optimize sensor layouts, ensuring high precision and outstanding performance.

-

Electronic Readout Systems

We design electronic readout systems for sensor interrogation, covering comprehensive firmware, hardware, and software solutions.

-

Diagnostics and Prognostics

Our non-invasive sensors support advanced diagnostics and real-time data collection, enabling data-driven decisions in production processes.

With expertise ranging from design to commercialization, HighSenseTech is committed to delivering innovative solutions in partnership with industry leaders to enhance production processes.

Clients & Partners

Services & Expertise

Our Professional Services and Technical Expertise

Technical Consulting

Our team provides expert consulting on MEMS integration, sensor data analysis, and optimal sensor deployment to enhance your systems.

MEMS Fabrication Services

We offer advanced MEMS fabrication services tailored to your project requirements, ensuring precision and high-quality production standards.

Products & Applications

Our Main Product and Its Versatile Applications

High-Resolution MEMS Sensor

Learn More

Geoscience and Geohazard Strain Monitoring

Learn More

High performance weighing system

Learn More

Valve pressure measurement

Learn More

Structural Health Monitoring

Learn More

6 6DoF Load Cell

Learn More

Our Hardworking Team

Meet the Team

Our Expertise

- MEMS Sensor Design and Fabrication: Extensive experience in designing and fabricating physical MEMS sensors on silicon technology, backed by advanced FEM modeling for sensor layout optimization.

- Electronic Readout Systems: Proficiency in developing electronic readout systems essential for sensor interrogation and data acquisition, covering firmware, hardware, and software solutions.

- Mechanical and Packaging Design: Expertise in mechanical and packaging design to enable seamless integration of electronics into complex measurement systems.

- Market and Regulatory Strategy: Strategic understanding of market dynamics, regulatory compliance, and effective product positioning, supporting successful commercialization.

Our active participation in National and European projects highlights our capacity to navigate complex technological landscapes and advance sensor technology applications.

Matteo Ferri

Chief Executive Officer

Luca Belsito

Chief Financial and Technology Officer

Federico Zardi

Chief Product OfficerF.A.Q

Frequently Asked Questions

How does the HRSS differ from traditional strain sensors?

The HRSS provides up to 1000× higher resolution compared to conventional strain gauges. This enables the detection of extremely small strain variations, unlocking new opportunities in diagnostics, quality control, and the design of advanced measurement systems.

What kind of practical applications are enabled by this technology?

The extremely high resolution of the HRSS allows the measurement of different physical quantities by

exploiting the physics of the phenomenon under study. For example, torque applied to a shaft induces strain on

the surrounding housing: by measuring this strain non-invasively, torque can be directly derived.

The same principle applies to force, pressure, and other quantities. A typical workflow involves running a

FEM (Finite Element Method) simulation to analyze the correlation between the target quantity

and the induced strain, followed by bonding the sensor to the external surface of the component. This makes

HRSS a versatile and non-invasive transducer adaptable to many industrial and robotic applications.

Does the sensor need to be embedded inside the component?

No. A key advantage of the HRSS is its capability for non-invasive integration. The sensor can be bonded directly to the outer surface of a mechanical component or structural element, enabling accurate measurement of physical quantities such as force, torque, or pressure without modifying the internal geometry. This reduces design complexity, lowers implementation costs, and preserves the mechanical integrity of the system under test.

What is the sensor bandwidth?

The HRSS can operate with bandwidths in the kHz range. This is crucial in applications requiring fast and precise closed-loop force control, such as collaborative robotics, delicate manipulation, or high-speed assembly processes. In industrial contexts, wide bandwidth also allows capturing rapid transients and maintaining stability in systems with complex dynamics.

What advantages does the HRSS provide in load cell design?

Thanks to its ultra-high resolution, the HRSS enables the development of ultra-stiff load cells that ensure mechanical stability while maintaining exceptional sensitivity. Furthermore, it allows the realization of load cells with an extremely wide dynamic range, capable of accurately measuring both very small and very large loads, opening new opportunities for high-performance applications.

Contact

Need Help? Contact Us

Address

Gobetti 101, 40129 Bologna, Italy

Call Us

+39 051 6399110

Email Us

info@highsensetech.com