High Resolution Strain Sensor

Sensor Overview

- Category: Industrial Diagnostics

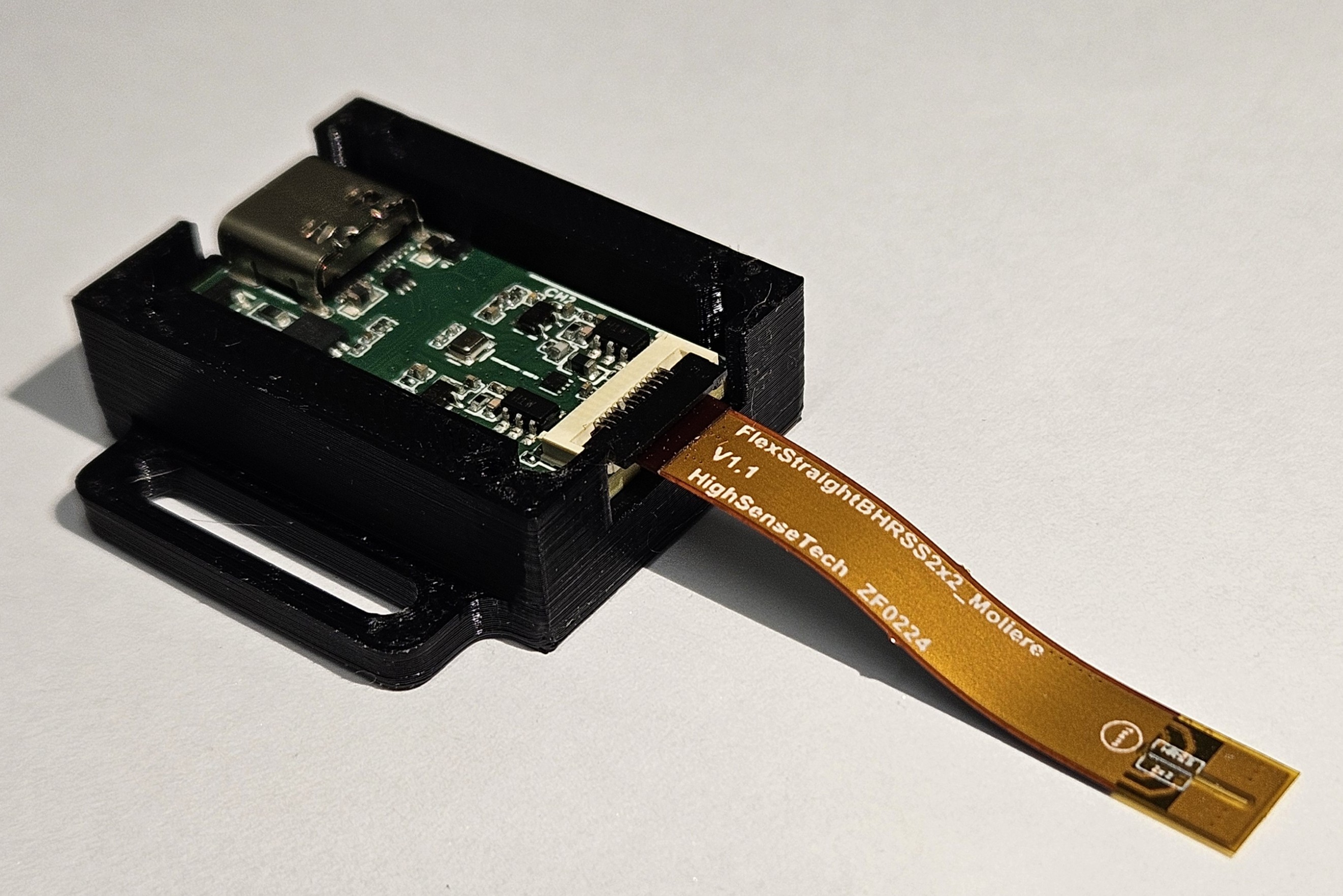

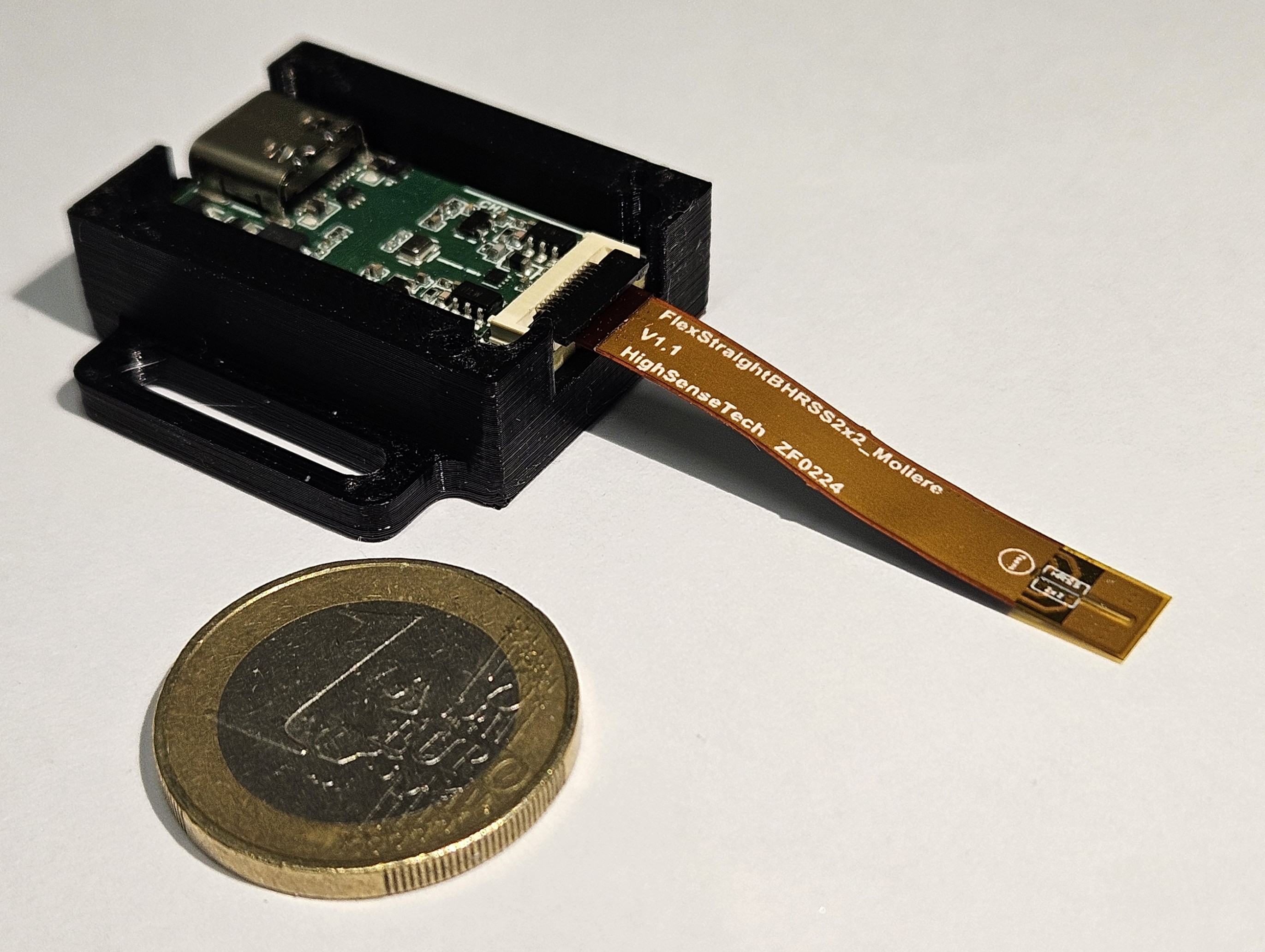

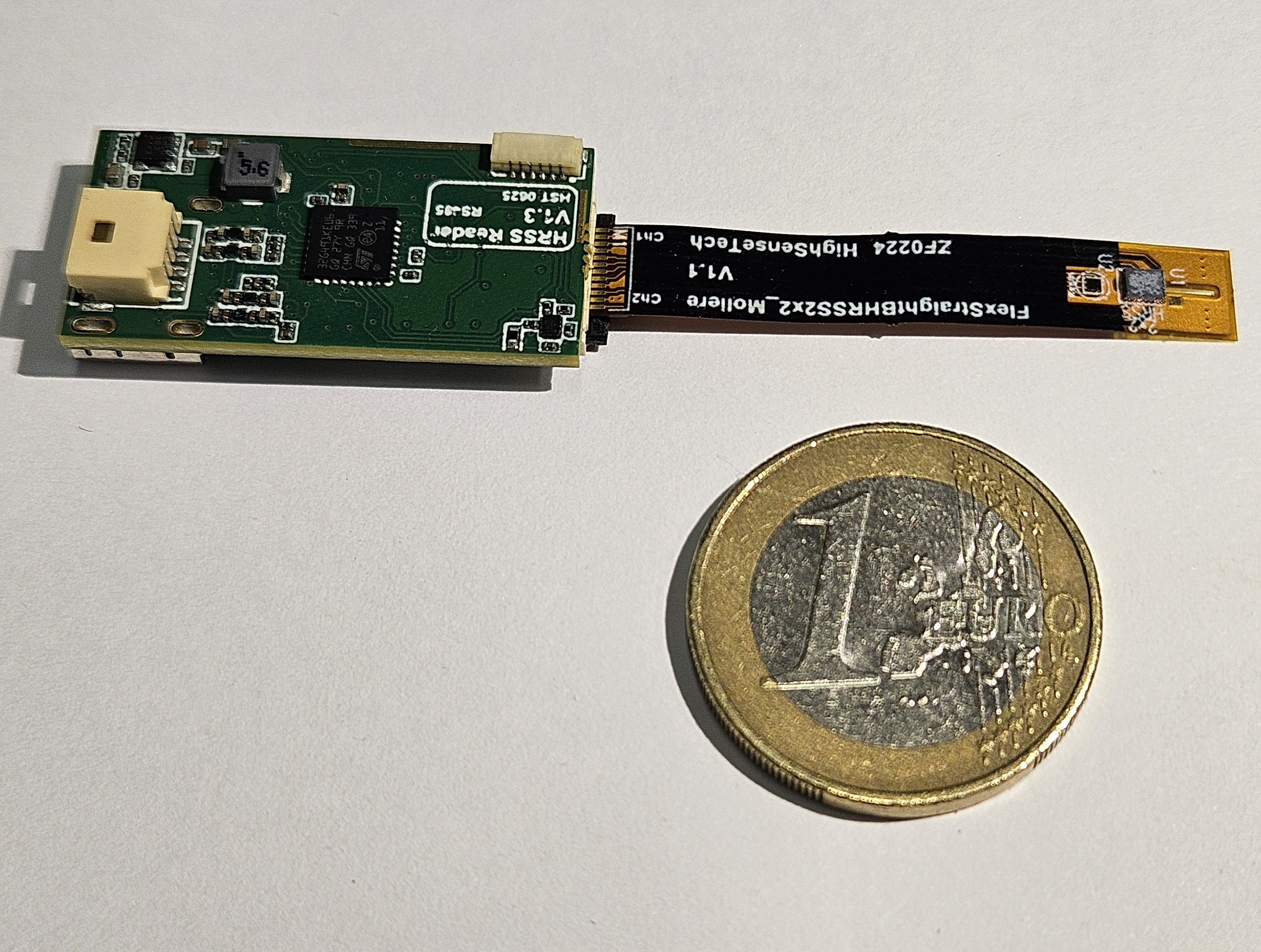

- Device: High-resolution MEMS Strain Sensor

- Applications: Unlocking new possibilities in precision sensing: from measuring force, pressure, and torque to enabling advanced control in automation, robotics, geotechnical monitoring, and beyond.

Innovative High-Resolution Strain Measurement

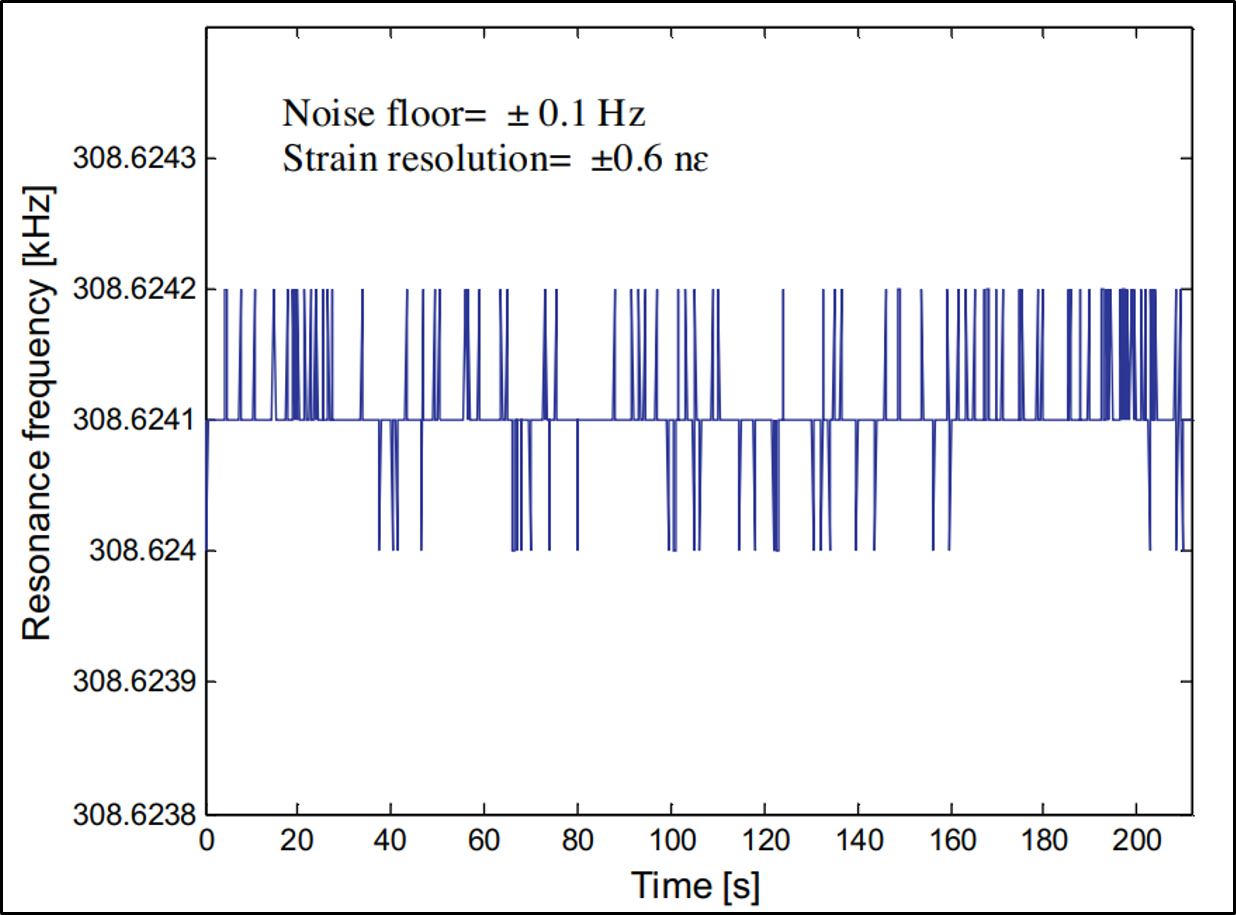

Our MEMS strain sensor utilizes a resonant micromechanical design, offering unprecedented precision in strain detection. Like tuning a guitar string, the sensor’s resonance frequency shifts in response to applied forces, making it highly sensitive to even minute deformations.

Advanced Features

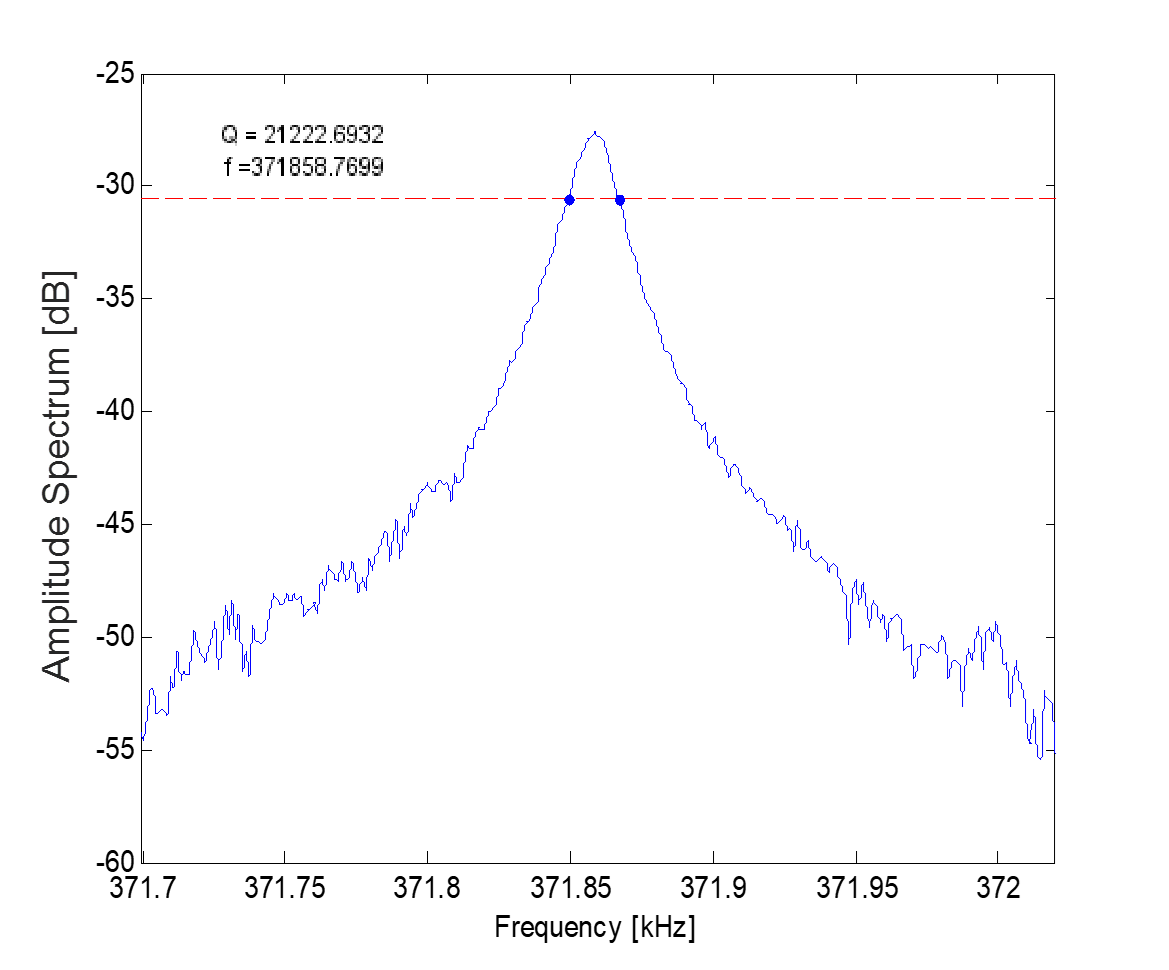

- High Quality Factor: With a Q-factor exceeding 20,000, phase noise is minimized, enhancing resolution.

- Low Power Consumption: Suitable for battery-operated devices, thanks to its electrostatic actuation.

- Non-Invasive Installation: Seamless integration without modifying the host device’s performance.

Download the Brochure

Get detailed specifications and technical information about our MEMS Strain Sensor.

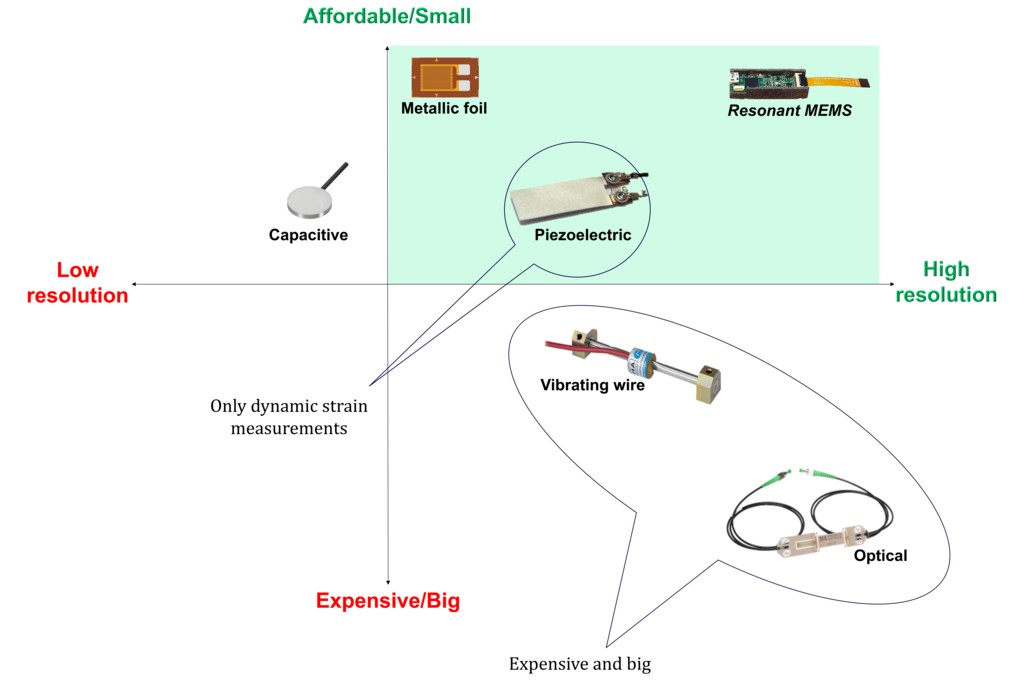

Download BrochurePerformance Comparison

See how our MEMS Strain Sensor stands out against traditional strain sensors.

| Feature | MEMS Strain Sensor | Traditional Metal Strain Gauge |

|---|---|---|

| Resolution | High (up to 20,000 Q-factor) | Low |

| Power Consumption | Low (battery-operated) | High |

| Size | Compact, lightweight | Larger |

| Installation | Non-invasive | Intrusive |

| Cost-Effectiveness | Scalable with production volume | Limited scalability |

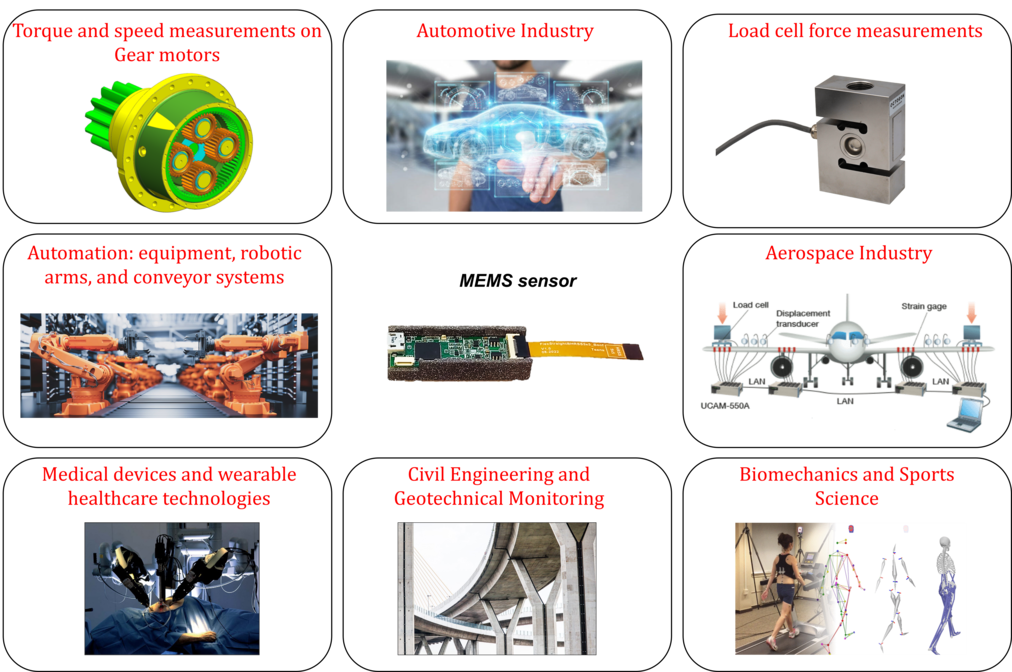

Applications

Our MEMS Strain Sensor is versatile and suited for a wide range of applications:

- Load Cell Force Measurement: Accurate force measurement in load cells for various industries.

- Geotechnical Monitoring: Real-time strain monitoring in geological applications for safety and diagnostics.

- Automation: Integration with robotic arms, conveyor systems, and industrial equipment.

- Biomechanics & Sports Science: Precise strain measurement for research and athletic performance monitoring.

- Aerospace & Automotive: High-resolution strain monitoring for enhanced diagnostics and safety.

- Medical Devices & Wearables: Compact and non-invasive, ideal for health monitoring applications.

- Hydraulic and Pneumatic Systems: Non-invasive pressure and strain monitoring on valves and motors.

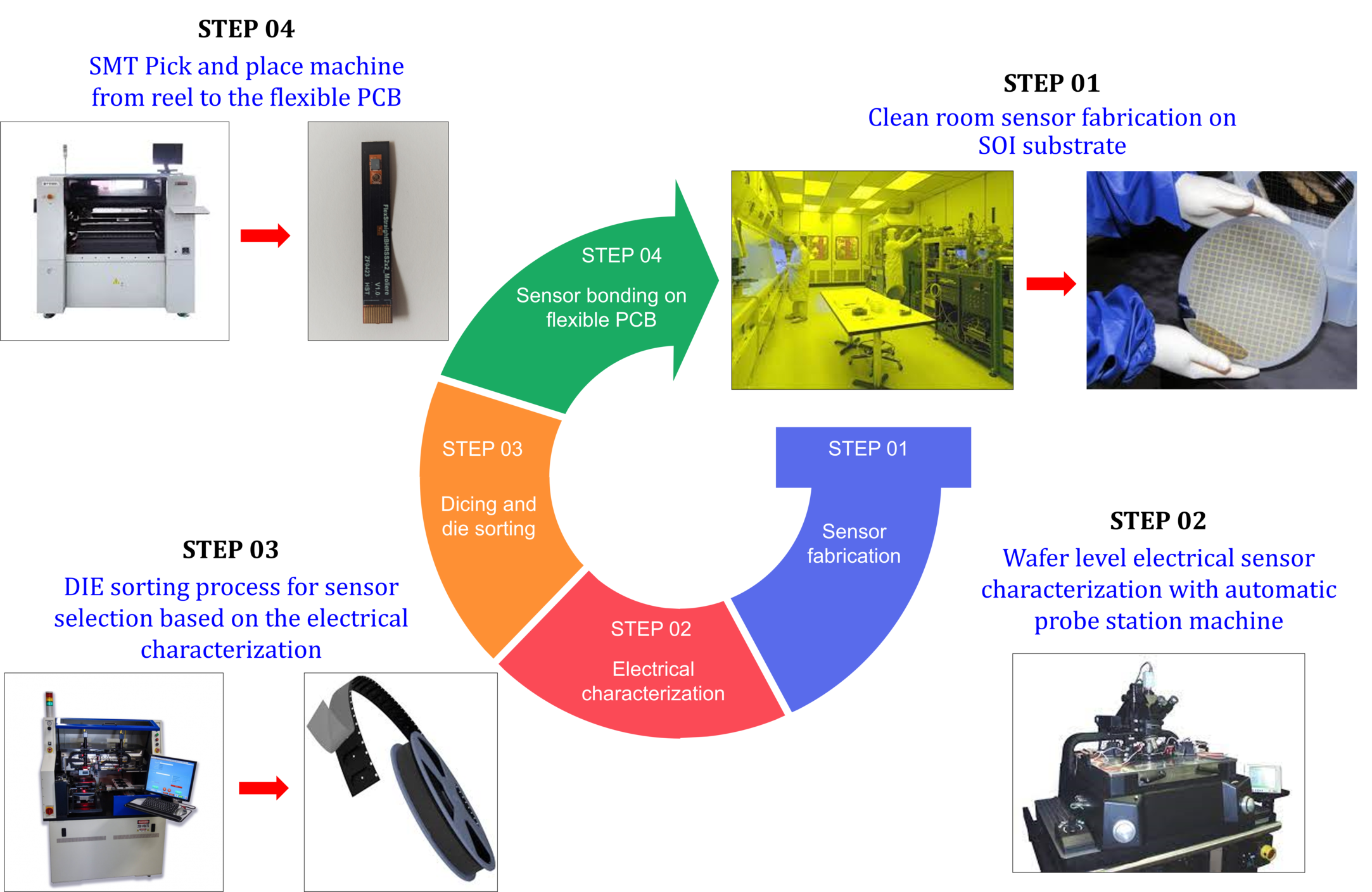

Sensor Fabrication Process Flow

This diagram illustrates the step-by-step process of fabricating our MEMS strain sensor, from initial fabrication to final assembly on a flexible PCB.